Electrical parameters

Working voltage: flexibly adaptable to 24V DC, 120V AC or 220-380V AC to meet the needs of different industrial scenarios.

Input/output channels:

Binary input module (BIM): provides 16 input channels (some models support pulse counting function, suitable for frequency measurement or event counting).

Binary output module (BOM): configured with 12 groups of 24 relay output channels, supporting large current capacity (such as 10 output channels divided into 3 groups, including 2 high-speed relays, suitable for tripping output or time synchronization and other scenarios).

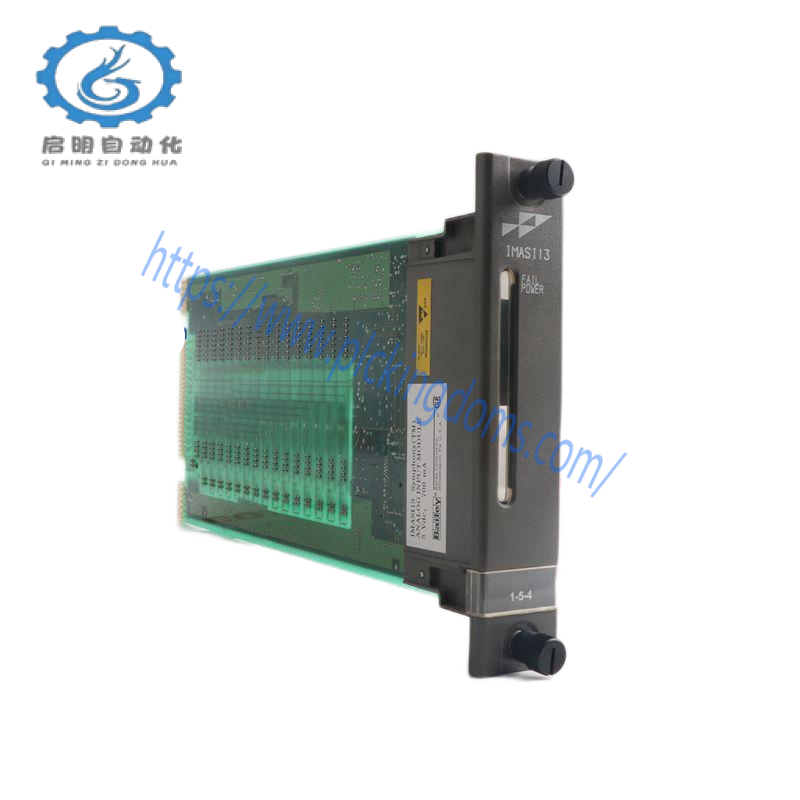

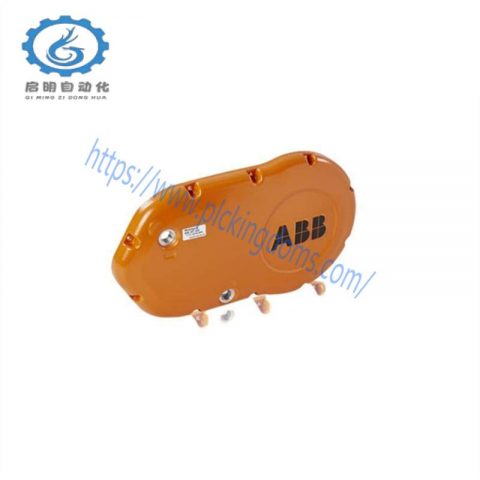

Physical size: The packaging size is about 110mm×106mm×20mm, and the weight is about 1.2kg, which is easy to integrate into a compact control cabinet.

Communication interface

Standard protocol: supports industrial protocols such as Modbus, PROFIBUS, Ethernet/IP, etc., to ensure seamless connection with multi-brand equipment.

Expansion capability: The communication function can be expanded through the F series communication module, but it should be noted that some I/O points will be reduced.

Core features

Anti-interference and stability

Strong anti-electromagnetic interference capability: meets industrial environment standards and can operate stably under extreme conditions.

Local timestamp and signal identification: each I/O event is accompanied by a timestamp, supports software identification of oscillation signals, and improves fault diagnosis efficiency.

Input/output optimization

Battery ground fault tolerance: even if the battery power supply grounds fault, the input signal can still work normally to ensure system continuity.

Large current output support: binary output modules support high load requirements (such as trip output or signal control), and some channels can reach 10A current capacity.

Flexible configuration

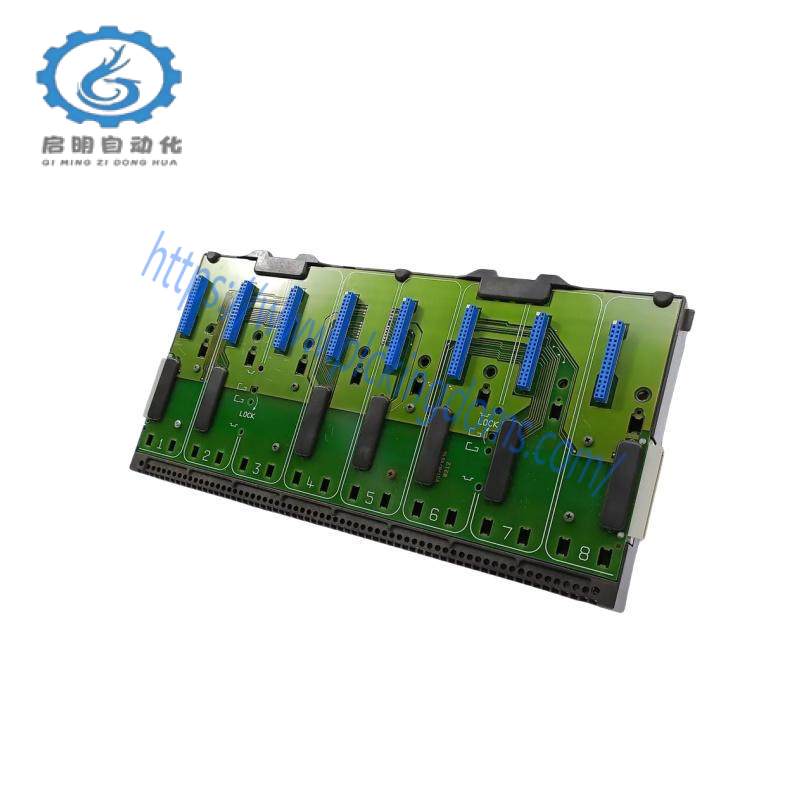

Modular design: BIM (input) or BOM (output) modules can be selected according to needs, or mixed.

High-speed signal channel: some models provide dedicated high-speed relay output (response time ≤1ms), suitable for time synchronization or fast response scenarios.

Typical application scenarios

Process control industry

Chemical/petroleum: used in key links such as reactor temperature control and pipeline pressure monitoring, and flow measurement is achieved through pulse counting function.

Power/Metallurgy: Realize generator status monitoring and blast furnace automation control, support high current tripping output to ensure equipment safety.

Manufacturing Automation

Production Line Control: Integrate into PLC system to manage the collaborative operation of robots, conveyor belts and other equipment, and achieve precise synchronization through high-speed output channels.

Equipment Monitoring: Collect sensor data (such as temperature and pressure) in real time through analog input channels to optimize production processes.

Energy and Building Management

Power System: Used for substation automation and power quality monitoring, support multi-protocol communication to achieve data interconnection.

Smart Building: Control lighting and air conditioning systems, and achieve energy saving and comfort balance through binary output modules.

Compatibility and Scalability

Multi-protocol Support

Compatible with mainstream protocols such as Modbus, PROFIBUS, Ethernet/IP, etc., and can be networked with brand equipment such as Siemens and Schneider to reduce the difficulty of system integration.

Optional expansion

BIO-01 board: Add 3 DI, 1 DO and 1 AI input to make up for the reduction of I/O points caused by F series communication modules, suitable for complex control scenarios.

RAIO-01 module: Expand analog output channels, support 0-20mA/4-20mA signals, and meet the needs of analog quantity in process control.

System integration

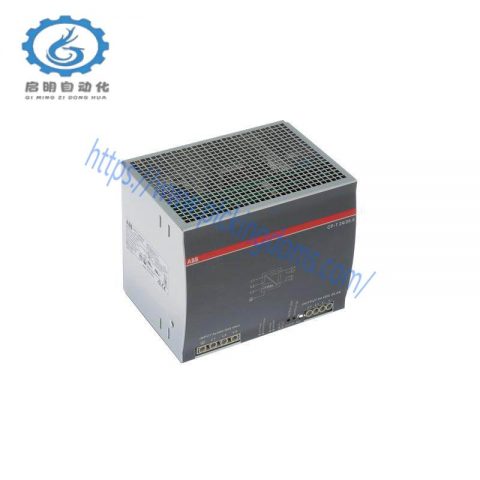

ABB AC500 series ecosystem: can work with DCS50 inverter, GFD563A controller, etc. to build a complete automation solution.

Distributed I/O expansion: can be expanded to 7 I/O modules through FBP bus, support local or remote deployment, and reduce wiring costs.

Summary

ABB 500PSM03 1MRB150038R1 input and output module is widely used in key areas of industrial automation with high reliability, strong anti-interference and flexible configuration as its core advantages. Its modular design, multi-protocol support and rich expansion options enable it to adapt to complex industrial environments and become an ideal choice for improving production efficiency and system stability. Whether it is process control, manufacturing automation or energy management, this module can provide precise signal conversion and control command transmission, helping enterprises achieve digital transformation and intelligent upgrading.

Related product recommendations:

3BHB018008R0003

S-073N 3BHB009884R00211

3BHB009884R00211

S-123H 3BHB030479R0512

3BHB030479R0512

S-093M 3BHB009885R0013

3BHB009885R0013

S-097H 3BHB009885R0052

3BHB009885R0052

3BHB009885R0063

S-093M 3BHB009885R0063

3BHB009885R0005

S-093H 3BHB009885R0005

3BHB009885R5311

S-093R 3BHB009885R5311

3BHB009885R0004

More…

There are no reviews yet.