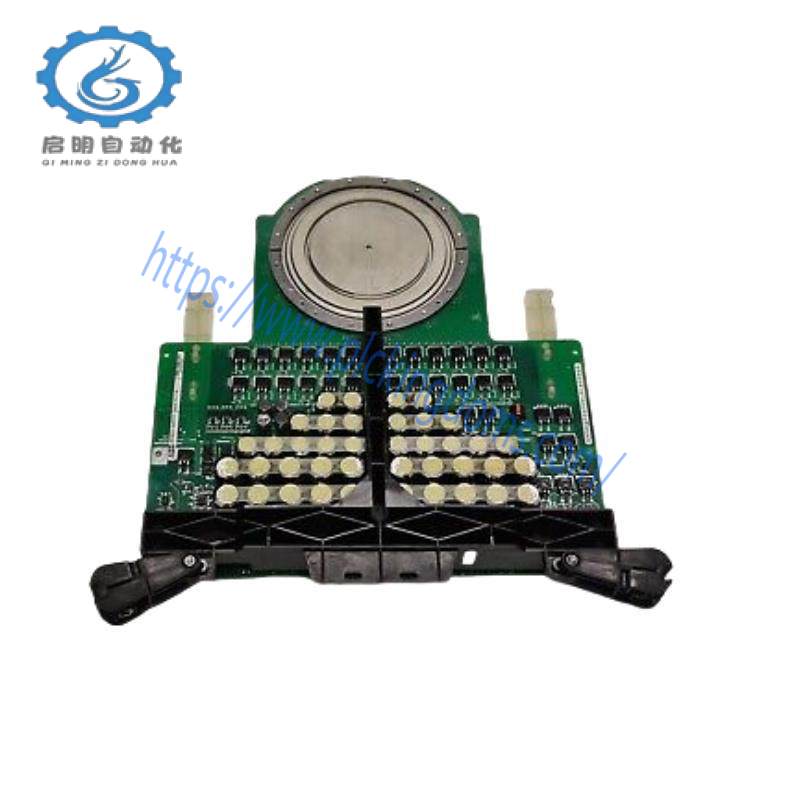

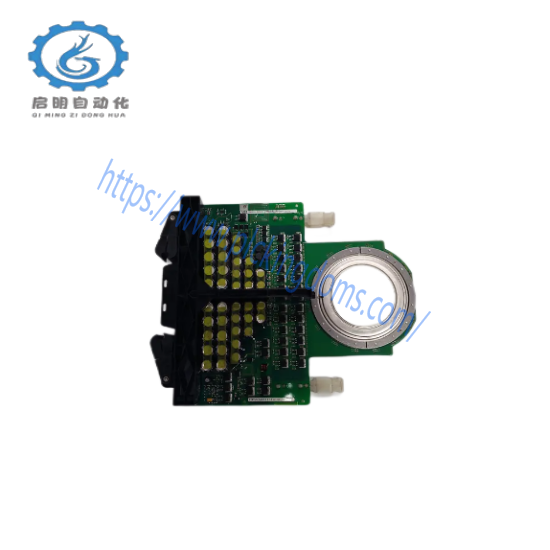

The 3BHS817511 E30 is a core power distribution unit designed by ABB for medium- and high-voltage power grids and large industrial variable-frequency drive systems (such as the ACS6000 and PCS6000 series). It functions as a grid breaker unit or gate board unit. Its core functions include:

Circuit Control and Protection

On/Off Control: A high-speed DSP + FPGA processor enables precise switching control of IGCTs/IGBTs (response time <1μs), optimizing switching losses and improving converter efficiency (>98%).

Power Distribution: Optimizes power distribution to various devices or branch circuits, improving transmission efficiency.

Multiple Protection: Integrated protection mechanisms include overload, short-circuit, undervoltage, overvoltage, and arc extinguishing. For example, a short-circuit response time of <1μs allows for rapid fault isolation; undervoltage automatically disconnects the circuit to prevent equipment damage. Redundant protection circuit design is supported, making it suitable for harsh industrial environments such as metallurgy, mining, and chemical industries.

Power Management: Controls grid-connected/off-grid switching, enabling power distribution and dynamic regulation to ensure stable operation of motors (such as induction and synchronous motors).

Drive and Control

Power Device Drive: Precisely controls power semiconductors such as IGCTs/IGBTs (such as 4500V/4000A modules) to reduce switching losses and improve converter efficiency.

Intelligent Monitoring: Communicates with a master controller (such as the AC800PEC) via optical fiber, supporting the MODBUS protocol, providing real-time status feedback and fault detection.

System Compatibility

Designed specifically for ABB ACS6000, ACS5000, and DCS series inverters, it is suitable for high-power motor control (such as in metallurgy, mining, cement, and chemical equipment).

Applications include rail transit (subway traction converters), renewable energy (wind turbine converters), and marine propulsion systems, supporting four-quadrant bidirectional power flow.

Technical Parameters and Specifications

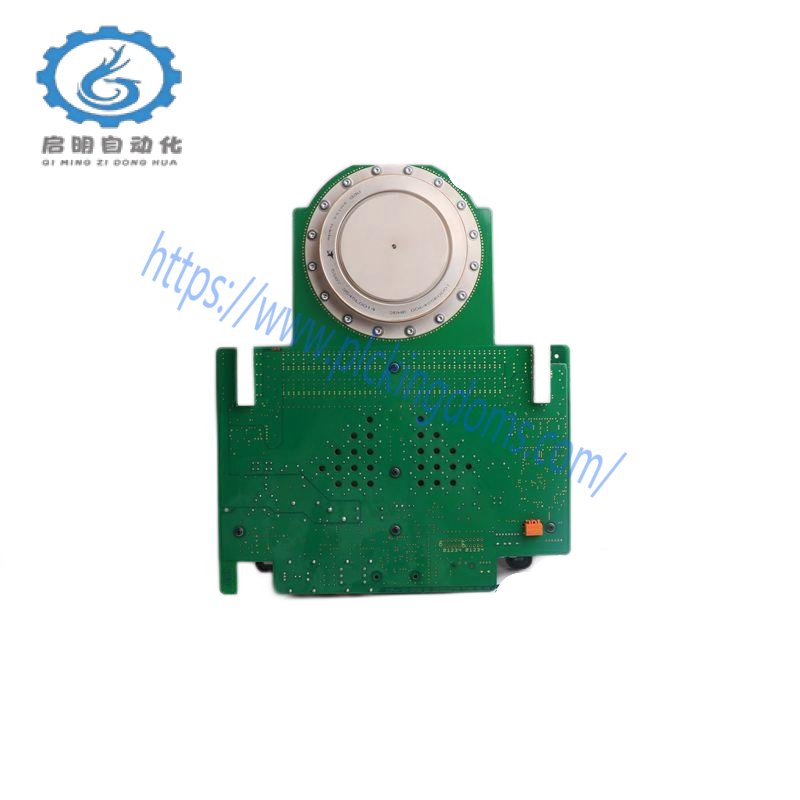

Model Identification: Typical model number is 3BHS817511 E30 , rated voltage 4500V, rated current 4000A (depending on cooling conditions).

Communication Interface: Connects to a host controller (such as an AC 800PEC PLC) via optical fiber, supports MODBUS or custom protocols, and is compatible with ABB DTC (Direct Torque Control) technology.

Environmental Adaptability: Protection levels are selectable: IP32/IP42/IP54, operating temperature 0-40°C (expandable to higher altitudes/temperatures with derating), noise level <75dBA.

Cooling System: Supports both air and water cooling modes, with an integrated dual-pump redundant design to ensure reliable heat dissipation.

Core Positioning and Technical Architecture

System Affiliation: The 3BHS817511 E30 (Grid Breaker Unit) is the core power distribution unit of the ABB ACS6000 medium-voltage drive system. It is a grid circuit breaker control module, suitable for power ranges from 3-36 MW and voltage levels from 3.3 kV to 4.16 kV. Its modular design supports hot swapping and is compatible with common DC bus architectures. It is widely used in industrial drives, rail transit, renewable energy (such as wind power), and grid support scenarios.

Control Core: Integrated IGCT/IGBT drive logic, using a three-level VSI-NPC topology, supports four-quadrant operation (bidirectional energy flow). It communicates with a master controller (such as the AC800PEC) via optical fiber and is compatible with industrial protocols such as Modbus RTU and PROFIBUS, achieving millisecond-level torque/speed response.

Protection Mechanism: Built-in overload, short-circuit, overvoltage/undervoltage, and ground fault protection with a response time of ≤1μs and support for fast safety shutdown (FRT), compliant with IEEE 519 and IEC 61000-4-2/3 standards.

Key Functions and Technical Parameters

Electrical Characteristics:

Rated voltage: 4500V (DC bus), maximum load current 4000A (subject to cooling conditions).

Interface Configuration: 24VDC power input, fiber optic communication port, current/voltage monitoring interface, and support for redundant power supply design.

Arc Extinguishment: Advanced arc extinguishing chamber design limits short-circuit current peaks, reducing the risk of equipment damage.

Scalability: Modular structure supports parallel expansion to meet different power requirements. Compatible with ABB ACS6000/PCS6000 series and can be integrated with DCS/PLC systems from brands such as Siemens and GE.

Special Applications:

Industrial Scenarios: Control of high-power motors in metallurgical rolling mills, mine hoists, and cement plants, achieving precise phase synchronization and energy recovery.

Metallurgy/Mining: Used for controlling high-power motors in mine hoists, rolling mills, conveyor belts, and other applications. For example, a coal mine’s ACS6000 system uses the 3BHS817511 E30 to implement 10kV high-voltage trip protection, preventing over-tripping.

Power Transmission: In HVDC (High Voltage Direct Current) and FACTS (Flexible Alternating Current Transmission) systems, it serves as the valve hall control core for converter stations, supporting cross-regional power transmission and renewable energy grid integration.

Renewable Energy: Wind power converter systems (compatible with 14MW turbines) ensure stable operation of IGCTs under grid fluctuations; offshore wind power is designed for high temperature and high humidity environments.

Rail Transit: Subway traction converters achieve smooth acceleration and braking, reducing energy consumption and failure rates.

Special Projects:

NASA Wind Tunnel: A 101MW inverter integrates a 3BHS817511 E30 , driving a 135,000hp synchronous motor, setting a world record for power and size.

Ormen Lange Gas Pipeline: Three 48MW MEGADRIVE-LCIs drive compressors, utilizing the 3BHS817511 E30 for efficient power conversion and fault isolation.

Application Scenarios and Advantages

Grid Compatibility: Meets Low Voltage Ride-Through (LVRT) requirements, supports dynamic reactive power compensation (20-100 Mvar), and improves transmission capacity. Total Harmonic Distortion (THD) is <3%, compatible with various global grid standards (e.g., 85-264V AC input).

Environmental Adaptability: Dual-mode cooling system (forced air/liquid cooling), operating temperature range -25°C to +70°C, and IP20 protection rating (expandable to IP54), making it suitable for harsh environments such as mines and offshore platforms.

System Advantages:

High Reliability: IGCT technology reduces component count, extends service life, and is SIL 3 (IEC 61508) certified.

Low Lifecycle Cost: Modular maintenance reduces downtime, and remote monitoring supports predictive maintenance, resulting in an MTBF exceeding 100,000 hours.

Flexibility: Supports customized power requirements and adapts to multi-motor coordinated operation and energy recovery scenarios.

Maintenance and Troubleshooting

Daily Maintenance: Regularly check module status (LED indicators, heat dissipation), DC bus voltage, and filter status. It is recommended to thoroughly check capacitor status and gate voltage every 5,000 hours, clean the air filter every 6-12 months, and replace the cooling fan every 3 years.

Physical Inspection: Regularly clean dust, inspect cables and fiber optic connectors for looseness or contamination, and ensure proper ventilation and heat dissipation.

Electrical Testing: Perform insulation tests, wiring checks, verify grounding reliability, and prevent electromagnetic interference.

Software Monitoring: Monitor operating status through system diagnostics and respond promptly to abnormal alarms.

Troubleshooting:

Typical Case: A coal mine’s ACS6000 system was experiencing frequent tripping. Troubleshooting revealed discharge in the IFU unit’s incoming line filter reactor. Stable operation was restored after replacing the GUSP power supply unit.

Key Steps: Check the IGCT module’s conduction characteristics, capacitor bank status, cooling system conductivity and pressure, and confirm the reliability of the circuit breaker’s main contacts and busbar connections.

Troubleshooting:

Common faults: Contact sticking, signal loss, power supply anomalies, and IGCT damage.

Handling Process: Identify the faulty module based on the fault code and replace it via hot-swap; use a multimeter/oscilloscope to monitor gate voltage and current waveforms; and analyze fault logger data using DriveWindow software. For example, in a coal mine hoist failure, checking the IGCT and diode performance identified an unstable clamping diode, VC1. Replacement restored normal operation.

Application Scenarios and Advantages

Industrial: Enables smooth motor acceleration/braking and rapid power-off protection in metallurgical rolling mills, mine hoists, and conveyor belts.

Energy and Transportation: Ensures stable operation of IGCTs in wind turbine converters; achieves efficient power management in marine electric propulsion systems.

Reliability: Integrated redundant protection circuits, IEC 60747-5-5 and UL certifications, and factory-tested with 100% power-on burn-in ensure long-term operational stability.

Synergetic Components and System Integration

Synergy with the ACS6000:

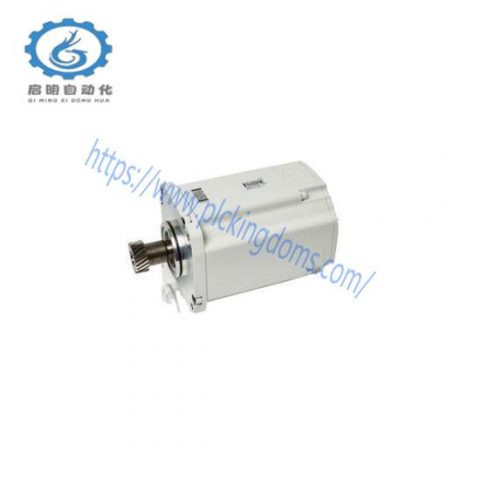

Topology: In single-drive or multi-drive configurations, the 3BHS817511 E30 works in conjunction with the ARU (Active Rectifier Unit), INU (Inverter Unit), and CBU (Capacitor Bank Unit) to achieve power conversion and dynamic response.

Power Range: Supports 3-27MW motor drives and is compatible with four-quadrant operation (such as brake energy regeneration), meeting the demanding requirements of industries such as metallurgy, petroleum, and shipbuilding.

Summary

The 3BHS817511 E30 is an indispensable power distribution core in the ACS6000 system. With its high-precision control, multiple protections, and modular design, it is widely used in high-power industrial scenarios, ensuring safe and efficient operation of power systems while also meeting the demands of emerging sectors such as renewable energy and rail transit. Its technical specifications and functional design demonstrate ABB’s leading technological expertise in the industrial drives field.

Related product recommendations:

IDPG 940128102

REM615C_D HCMJAEADAND2BNN1CD

OCAHG 492838402

CI626A 3BSE005029R1

5SHY3545L0016 3BHE019719R0101

5SHY3545L0016 3BHB020720R0002

PFSK151 3BSE018876R1

5SHY4045L0001 3BHB018162R0001

DSDI110AV1 3BSE018295R1

TC512V1 3BSE018059R1

DSDP170 57160001-ADF

3BSE000743R1

DSRF197 3BSE019297R1

More…..

There are no reviews yet.