Product Positioning and Core Value

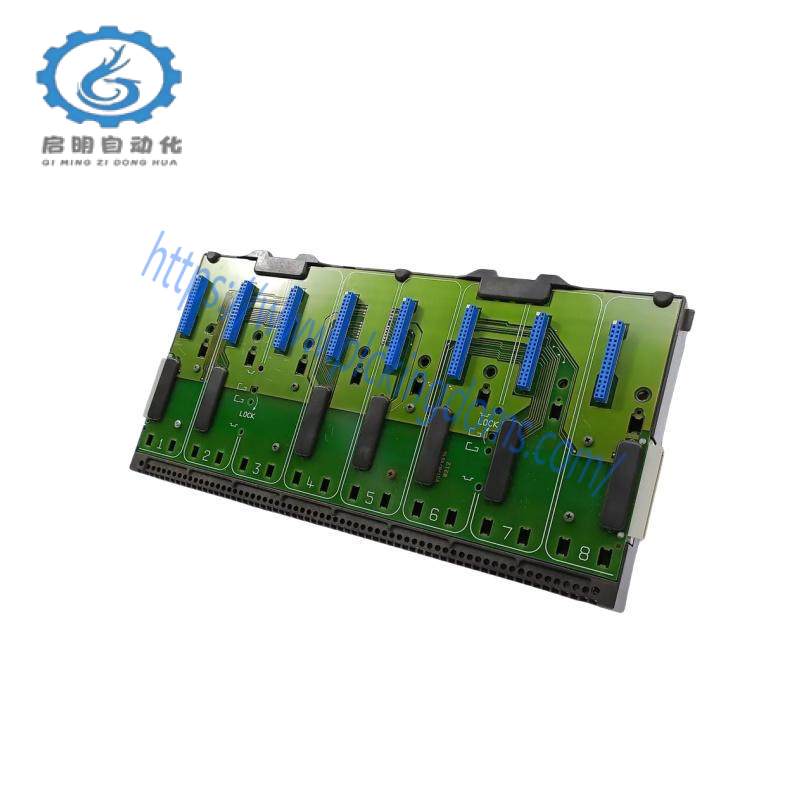

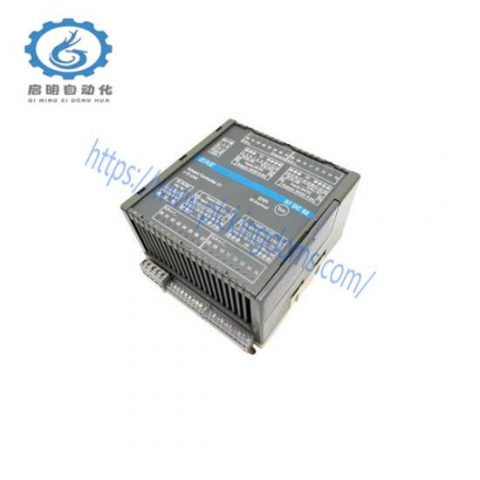

BDD110 HNLP205879R1 is a high-reliability binary output module in ABB’s industrial automation product line, designed for PLC (Programmable Logic Controller) or DCS (Distributed Control System) to convert digital control signals into switch actions of external devices (such as starting/stopping motors, opening/closing valves). Its core value lies in:

Stable control: Industrial-grade design ensures long-term stable operation in harsh environments.

Flexible expansion: Modular structure supports on-demand configuration of output channels to reduce system costs.

Fast response: Microsecond signal processing capability meets high-speed control requirements.

Basic parameters

Number of output channels: 8 independent channels (some models support 16 channels)

Output type:

Transistor output (common): NPN/PNP optional, suitable for DC 24V loads (such as solenoid valves, relay coils).

Relay output (model confirmation required): supports AC 220V/DC 24V, and can directly drive high-power devices such as contactors.

Load capacity:

Transistor type: 0.5-2A per channel (resistive load), 0.3-1A (inductive load).

Relay type: 5-10A per channel (AC/DC universal).

Response time: <1ms (transistor type), <10ms (relay type).

Electrical characteristics

Isolation voltage: 1500V AC isolation between channels, 3000V AC isolation between input/output and bus.

Overload protection: built-in short-circuit protection, automatically cut off the fault channel and alarm.

Reverse connection protection: prevent the module from being damaged due to reverse polarity of the power supply.

3. Communication and interface

Bus protocol: support PROFIBUS-DP, Modbus RTU/TCP, EtherCAT, etc. (depending on the configuration).

Address setting: through rotary switch or software configuration (such as ABB DriveWindow).

Status indication: each channel is equipped with an LED indicator to display the output status (on/off/fault) in real time.

Typical application scenarios

1. Process industry

Chemical production: control the reactor feed valve and the start and stop of the stirring motor.

Water treatment: adjust the switching frequency of the water pump and the dosing pump.

Power industry: control the circuit breaker opening and closing, and the indicator light status.

2. Machinery manufacturing

Packaging machinery: drive the cylinder action and the conveyor belt start and stop.

Textile machinery: control the yarn tension motor and the wire break detection alarm.

Machine tool control: switch the spindle speed and the coolant pump switch.

3. Building automation

Air conditioning system: adjust the fan speed and the electric valve opening.

Lighting control: group control of lighting scenes (such as conference mode and energy-saving mode).

Elevator system: control the door machine and the brake relay action.

Load type matching

Resistive load (such as heater): select transistor type and pay attention to the current margin.

Inductive load (such as motor, contactor): prioritize relay type, or transistor type + freewheeling diode.

Mixed load: Use relay output modules to simplify the design.

2. Environmental adaptability

High temperature environment: Select temperature-resistant modules (such as operating temperature -20℃~70℃).

Explosion-proof requirements: Confirm whether the module has passed ATEX/IECEx certification.

Vibration scenario: Select a reinforced design to prevent loose contact.

3. System integration

Protocol compatibility: Ensure that the module communication protocol matches the main control system (such as ABB 800xA, Siemens S7-1200).

Channel density: Select 8-way or 16-way modules according to the number of I/O points to optimize rack space.

Redundant design: Configure dual module hot standby in critical applications to improve system reliability.

Installation and commissioning guide

1. Mechanical installation

Rack installation: Use standard DIN rail (35mm width), and the recommended torque for fixing screws is 0.5-0.6N·m.

Heat dissipation design: Keep at least 10mm gap between modules to avoid overheating caused by stacking.

2. Electrical wiring

Power supply wiring:

DC 24V power supply: positive pole connected to module “V+”, negative pole connected to “GND”.

Avoid parallel wiring with power cables to reduce electromagnetic interference.

Load wiring:

Transistor output: one end of the load is connected to the module output end, and the other end is connected to the negative pole (NPN type) or positive pole (PNP type) of the power supply.

Relay output: directly connect AC/DC power supply and load.

Grounding treatment: The module housing is grounded through the shielded wire, and the grounding resistance is <1Ω.

3. Software configuration

Address setting: Assign the bus address through the DIP switch on the side of the module or the main control system software.

Parameter download: Use ABB Engineering Tool or third-party software (such as STEP 7) to upload/download configuration files.

Logic programming: Write ladder diagram (LAD) or function block diagram (FBD) in the main control system to associate input signals with output channels.

Troubleshooting and maintenance

1. Common problems

Output channel has no signal:

Check whether the power supply voltage is normal (DC 24V±10%).

Confirm whether the load is short-circuited or overloaded (triggering protection mechanism).

Verify whether the output command of the main control system is sent successfully.

LED indicator abnormality:

Red light is always on: channel is overloaded or short-circuited, and the load needs to be checked.

Green light flashes: communication is interrupted, check the bus connection or address setting.

Module temperature is too high:

Clean the dust of the cooling fan and improve ventilation conditions.

Reduce the number of channels that act simultaneously and reduce power consumption.

2. Preventive maintenance

Regular inspection: Check the tightness of the terminal blocks every quarter to prevent loosening and oxidation.

Spare parts management: Reserve spare parts for key modules to shorten downtime.

Summary

ABB 216BM61b binary output unit has become the preferred solution in the field of industrial automation due to its high reliability, flexible configuration and powerful functions. Users need to accurately select the model based on load characteristics, environmental conditions and system requirements, and strictly follow the installation and commissioning specifications to give full play to its performance advantages.

Related product recommendations:

REF543KB127AAAA

1MRK000838-HA

3BSE018681R1

PU519 3BSE018681R1

3BSE013064R1

PU516 3BSE013064R1

3BUR001401R1

PU512V2 3BUR001401R1

3BSE032402R1

PU516A 3BSE032402R1

3BSE032401R1

PU515A 3BSE032401R1

3BSE018876R1

PFSK151 3BSE018876R1

3BSE018876R1

PFSK151 3BSE018876R1

5SHX2645L0004 3BHL000389P0104

More……

There are no reviews yet.