Max Handling Capacity:Up to 261 chips per cycle

Precision Level:±0.02mm assembly accuracy

Automated Process:Fully automated assembly and inspection

Cycle Time:Less than 0.5 seconds per chip

Temperature Control:Precision temperature regulation for optimal soldering conditions

Software Compatibility:Integrated with industry-standard assembly software

Power Consumption:200W, energy-efficient operation

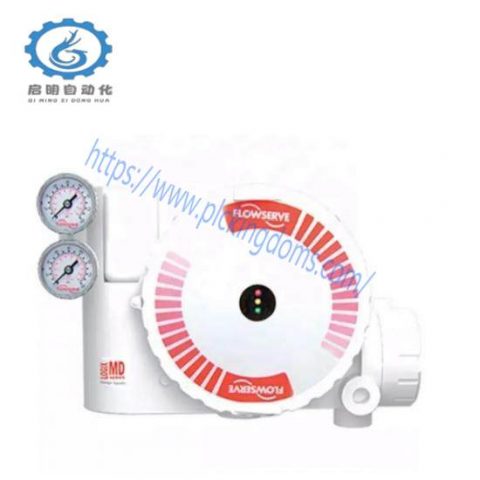

The K&S AS-261-0-02 is equipped with advanced robotics and precision optics, enabling it to handle a wide range of component sizes with unmatched accuracy. Its high-speed throughput rate allows for efficient production lines without compromising on quality.

Designed with user-friendliness in mind, this system features an intuitive control interface and robust software that simplifies setup and operation, making it accessible to technicians of varying skill levels.

Utilizing state-of-the-art cooling mechanisms, the AS-261-0-02 ensures consistent performance even under demanding conditions. This reliability is further enhanced by its durable construction and maintenance-friendly design, reducing downtime and minimizing repair costs.

Equipped with a comprehensive suite of sensors and inspection tools, the system guarantees high-quality assembly outcomes, significantly reducing rework and scrap rates. This translates to substantial cost savings and improved product quality for manufacturers.

Our dedicated support team provides comprehensive training and ongoing assistance, ensuring that your investment in the K&S AS-261-0-02 is backed by industry-leading expertise. From installation to routine maintenance, we are here to help you maximize productivity and efficiency.

There are no reviews yet.