Maximum Workpiece Size:720mm

Spindle Speed:24,000 RPM

Tool Capacity:24 tools

X/Y/Z Axis Travel:600mm x 500mm x 600mm

Precision Grade:ISO Class 3

Maximum Cutting Force:120kN

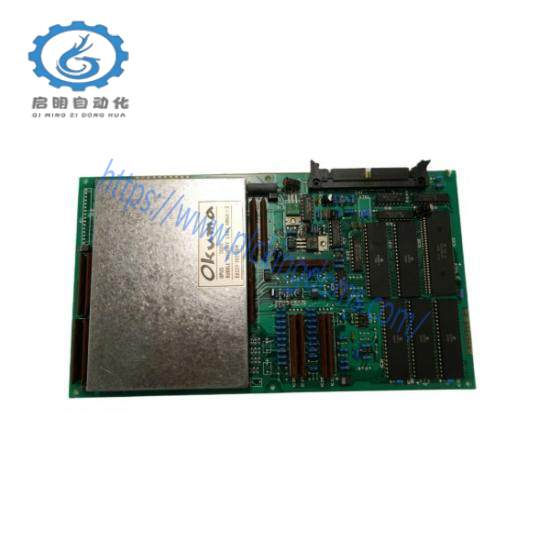

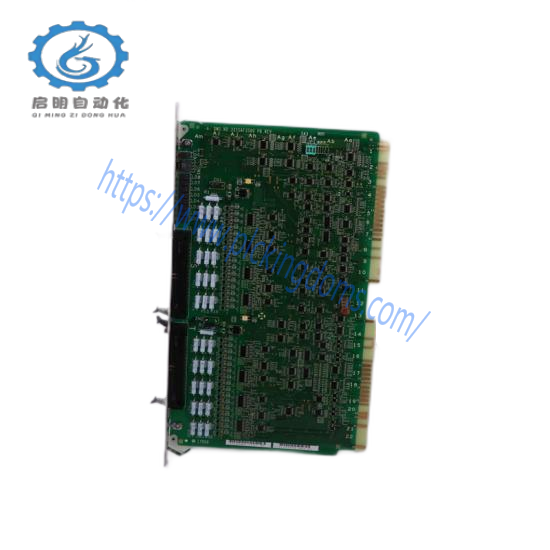

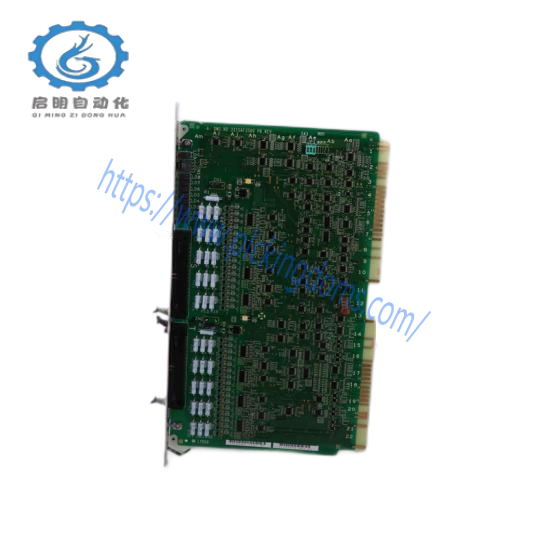

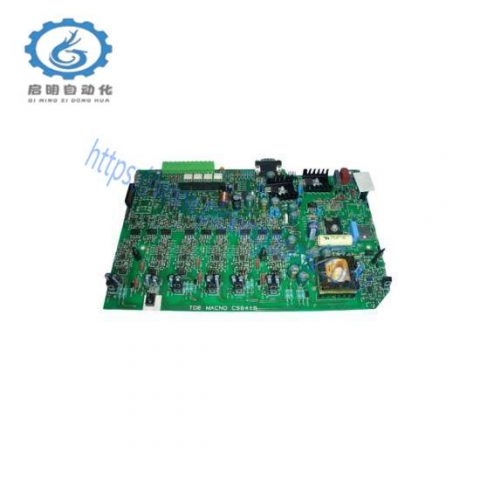

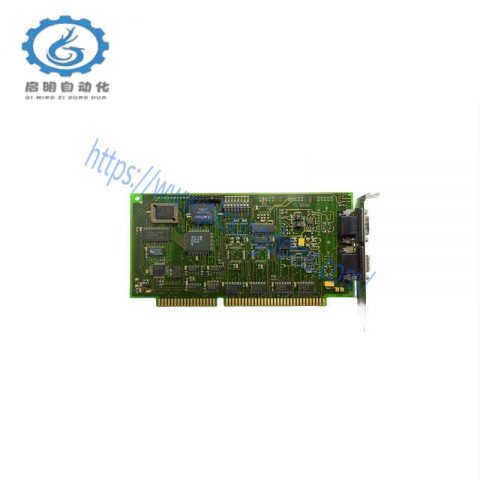

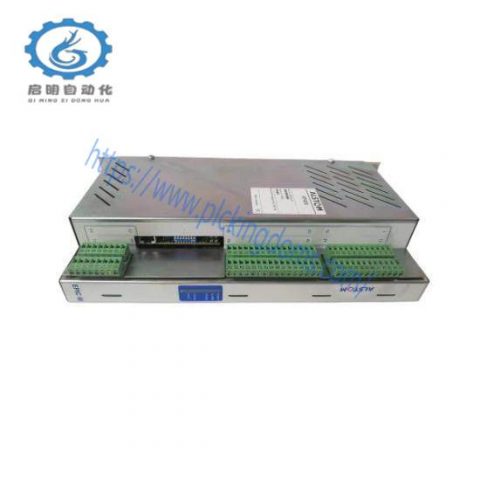

Electronics & Control System:Fanuc 0i-MF Control Unit

Coolant System:Fully Automatic with Overflow Prevention

The OKUMA ER-JG-7200D CNC Vertical Machining Center is engineered to deliver exceptional performance and reliability in the most demanding manufacturing environments. Its advanced automation capabilities enable seamless integration into Industry 4.0 production lines, ensuring optimal efficiency and productivity.

Featuring a high-capacity tool magazine and a robust spindle system, this machine is capable of handling a wide range of materials and intricate part geometries with unparalleled precision. The MITSUBISHI M-80B CNC system ensures smooth operation and intuitive control, making it accessible to both novice and experienced operators.

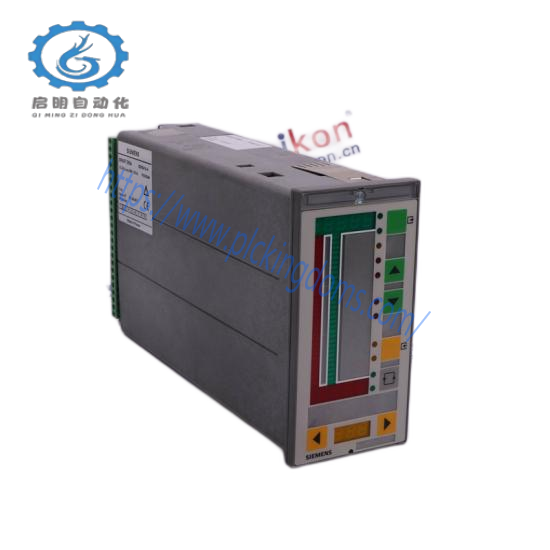

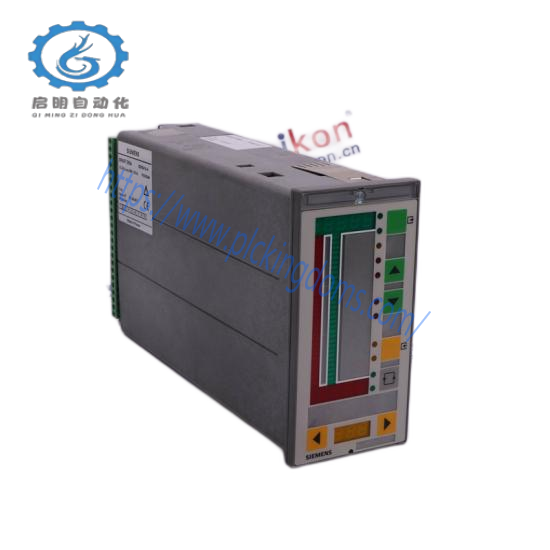

Designed with ergonomic considerations, the operator interface is user-friendly, offering quick access to essential functions and detailed job information. The machine’s compact yet spacious design maximizes floor space utilization, making it an ideal choice for facilities seeking to optimize their layout.

Safety and maintenance are prioritized with the inclusion of advanced monitoring systems that detect and alert operators to potential issues before they become critical. Regular maintenance intervals are scheduled, allowing for efficient service and minimizing downtime.

Backed by OKUMA’s renowned customer support and a comprehensive warranty, the ER-JG-7200D CNC Vertical Machining Center is not just a tool for manufacturing—it’s an investment in future-proofing your production capabilities.

There are no reviews yet.